NDT Control for Inline Production

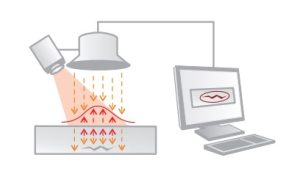

It works with the active thermography method. A heat source imparts thermal stimulation to the material under study. The effect of the stimulus on the material is recorded with an IR camera, and by analyzing the time-dependent heat flow with a series of thermal images obtained, the result image is created, which provides information about the smallest defects on the surface of the material and possible errors, inhomogeneities, and thermal irregularities in its internal structure.

For active thermography control, it is sufficient to connect the sensor head to the computer with IrNDT analysis software. C-CheckIR offers a flexible NDT system with sensor that can be used for mobile controls and inline production processes.

It offers non-contact and non-destructive measurement. It can be integrated into production lines, no surface and sample preparation is required. It provides the ideal real-time solution for composites and many other material types.

Temperature rise (ΔT) during measurement around +8 °C

Review time 10 – 25 seconds

Inspection area 430 mm x 340 mm

Weight (Sensor Head) Approx. 3.0 Kg (depending on system configuration)

Stimulus source: Halogen Lamp, Power 1.7 / 2.0 kW

For efficiency, wide area scanning can be performed and, if necessary, the measurement area can be expanded with a secondary stimulation source.

It is also possible to apply on vertical surfaces.

Outdoor version available; It is possible to adapt it according to ambient temperature and humidity conditions.

System advantages

- It detects errors at a high rate

- It can be integrated into production lines

- It results in short measurement times

- No surface and sample preparation is required

- IR system can be monitored continuously in the field

- Easy system configuration and maintenance

- Automatic loading of inspection parameters, automatic analysis and storage of inspection results

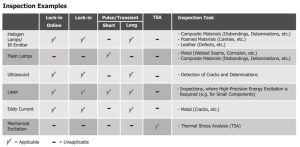

Error types it is sensitive to

- Corrosion - Porosity - Contamination - Delamination - Structural cracks - Impact damage - Fiber orientation - Adhesion problems - Clustering - Spot weld defects - Paint/coating thickness defects

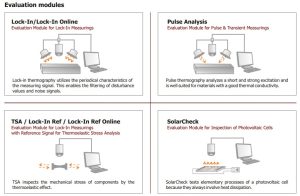

Configuration

Depending on the desired task, the basic package is defined by one or more evaluation modules. It varies depending on the type of warning source, its use and mathematical analysis. The system is optimally adapted to the material being analyzed by applying different measurement procedures.

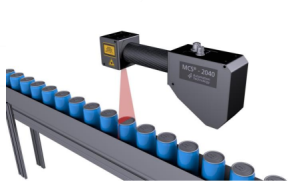

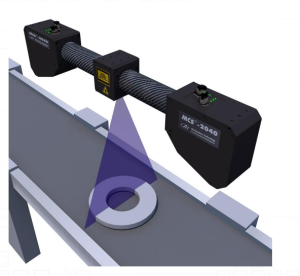

3D SENSORS

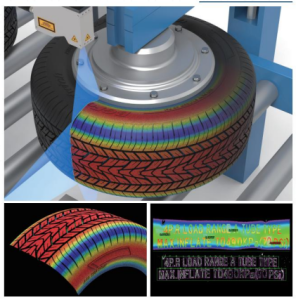

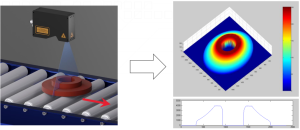

It offers an impressive combination of high speed and high-precision resolution, allowing 3D imaging to enter worlds never seen before. Available as compact sensor, modular compact sensor and 3D camera. Provides inline control.

The combination of high resolution with high profile speed allows the creation of high resolution scans at high transport speed, leading to better surface inspection; It allows finding smaller defects at higher production speeds.

• Wide range of 3D sensor models with resolutions of X-FOV 7-1800 mm and

• High profile speed with WARP technology up to 200kHz,

• Flexible and customizable 3D sensor designs with MCS, without NRE and MOQ,

• Available as triangulation cameras for use with customer-specific lenses and line projectors,

• Easy to integrate into any machine vision software application via GigE-Vision / GenICam 3.0,

Compact Sensors

✔ Calibrated 3D sensors ✔ Wide range of models from 7 to 1290 mm ✔ Four different sensor resolutions available (1280, 2040, 3070, 4090) ✔ High industrial protection class IP67 ✔ Various laser configurations ✔ Resolution up to 0.2 µm

Modular Compact Sensors

✔ Assembled and calibrated 3D laser sensors consisting of sensor module, laser module and connection module ✔ Four different sensor resolutions (1280, 2040, 3070, 4090) ✔ Features such as working distance, triangulation angle, number of points per profile, laser wavelength and laser safety class can be configured according to application requirements ✔ High industrial protection class (IP67)

3D Cameras

✔ Designed for flexible laser triangulation setups with user-defined lasers and lenses ✔ Four different sensor resolutions available (1280, 2040, 3070, 4090) ✔ High industrial protection class IP67 ✔ Available with a variety of lens mounts and adapters ✔ Lens protection tubes

project

Scope of application"METAROB's solutions,

"offers a wide range of applications."

project