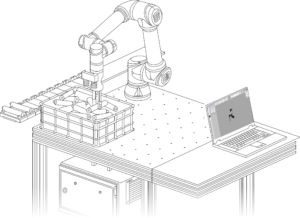

Image Processing Technology with Robot Integration

It can work integrated with robot arms in autonomous systems,

Quick installation and ease of connection with alternative robot brands,

Reliable results in all lighting conditions without the need for external light,

Wide range of tasks,

Processing with high precision and accuracy even on parts with a volume of 1mm3,

Sensitivity to various parts types and features such as transparent, shiny, metal, plastic, flat and more,

AI learns to detect collection points and parts identified independently and automatically by simulated data. The AI model calculates part positions and appropriate gripping points within 0.2 seconds. Selection points for the track are defined for 2-5 minutes per track. There is no need to learn on the real robot.

Installation is quick and easy. The user simply defines the gripping points.

Prediction time 200ms,

The minimum part size it detects is 1 mm x 1 mm x 1 mm,

Supported robot brands: ABB, Doosan, KUKA, Rokae, Universal Robots

Load the CAD model you want to select into the software. Identify ideal grip points on the CAD model.

Off-the-shelf cameras provide vision for AI.

The system learns a new task in a simulated environment running in the cloud, and this AI model is run on the local computer that commands the robot.

It is trained with commands such as take, place, add, locate. Add the camera position, get closer and start capturing.

Evaluating Employees in More Productive Tasks

By using artificial intelligence-supported systems for ordinary and repetitive tasks, existing human resources can be directed to tasks where they can be more productive.

Operating Cost Reduction

It can be integrated into various alternative tasks in business areas that produce 24/7 and can be positioned for different purposes.

Quality Increase

Repeatable tasks are possible with the same accuracy and precision.

Ability to Adapt to Changing Environmental Conditions

Preventing global supply chain problems

project

Scope of application"METAROB's solutions,

"offers a wide range of applications."

project